In the bustling world of food manufacturing, where efficiency and safety are paramount, the cleanliness of conveyor belts serves as a linchpin in ensuring product integrity and consumer wellbeing. These belts act as the lifelines of production, ferrying ingredients and finished goods through various stages of the manufacturing process. Any contamination on these belts can lead to disastrous consequences, including costly recalls, tarnished reputations, and, most importantly, compromised consumer health. Therefore, staying informed about the latest trends in conveyor belt cleaning methods is not just advisable but imperative for any food manufacturer striving for excellence.

Manual Cleaning Techniques:

While traditional, manual cleaning techniques involving brushes and handheld scrapers remain effective. Though labor-intensive, these methods offer a cost-effective solution, particularly suitable for small-scale operations. They enable thorough cleaning, especially in hard-to-reach areas where bacteria might lurk, ensuring optimal hygiene standards are maintained.

Automated Cleaning Systems:

For larger-scale operations, automated cleaning systems have become increasingly popular. Rotary brush cleaners, equipped with motorized brushes and sanitizing solution sprays, offer efficient and continuous cleaning along the conveyor belt’s length. By removing debris promptly, these systems minimize machine downtime and mitigate the risk of food contamination, enhancing productivity and safety simultaneously.

Water-Based Belt Cleaning Systems:

Water-based cleaning systems have gained prominence for their effectiveness in eliminating pathogens and biofilm from conveyor belts. Utilizing either low or high-pressure water jets, these systems deliver thorough cleaning without compromising food safety. Manufacturers can effectively manage food allergen risks while maintaining optimal cleanliness in their facilities.

Dry Steam Cleaning:

Innovative and environmentally friendly, dry steam cleaning harnesses high-temperature, low-moisture steam and mechanical agitation to dislodge stubborn debris from conveyor belts. The low moisture content of steam reduces the likelihood of mold and bacteria growth, aligning with stringent food safety standards. This method offers a potent yet gentle cleaning solution, ensuring the integrity of food products throughout the manufacturing process.

Dry Ice Blasting:

Emerging as a cutting-edge cleaning method, dry ice blasting presents a non-abrasive and non-toxic alternative for food manufacturing facilities. This technique involves blasting high-velocity dry ice pellets onto the conveyor belt surface, effectively removing dirt, debris, and contaminants without causing damage. As dry ice sublimates upon impact, it leaves behind no residue or waste, making it an environmentally sustainable choice for maintaining cleanliness in food production environments.

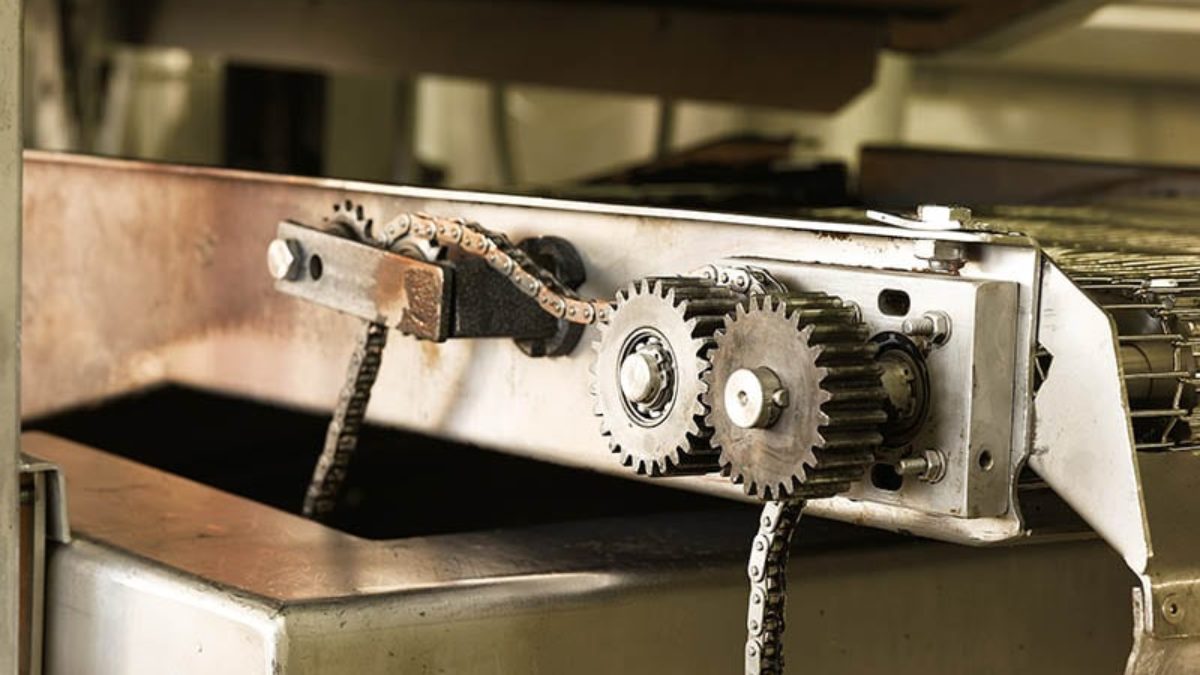

Ensuring proper cleaning of conveyor belts not only enhances food safety but also contributes to the longevity of the machinery and reduces the need for frequent maintenance. Clean conveyor belts experience less wear and tear, reducing the likelihood of breakdowns and extending the lifespan of the equipment. Additionally, by removing debris promptly, manufacturers can prevent accumulation in critical components, such as bearings and motors, minimizing the risk of costly repairs.

In instances where new conveyors are required or maintenance is necessary, partnering with reputable service providers is essential. Gottstein offers comprehensive installation and maintenance services, ensuring seamless integration of conveyor systems and reliable ongoing support. With our expertise, manufacturers can streamline operations, optimize equipment performance, and uphold the highest standards of cleanliness and safety in food manufacturing facilities.