The highest priority of project managers and engineers in any manufacturing facility is to ensure the safety of their team.

While most manufacturing facilities will have clear safety protocols for machinery, safety equipment, and construction safety, very often, fall risks are downplayed.

It is crucial that your team knows about the risks of workplace falls, what causes workplace falls, and how fall risks can be avoided.

Besides the risks to your team, OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces. For this reason, your team must abide by these standards to stay compliant.

In this article, we will look at some of the important safety protocols and how you can best train your team to reduce and eradicate fall accidents in your facility.

The High Risk of Falls, Trips, and Slips

Did you know that falls are the second highest cause of workplace fatalities, only behind transportation deaths?

Many employees do not realize that falling even a short distance can cause serious injury. The reality is falls that are even less than ten feet can cause a risk of injury and even death.

According to the Bureau of Labor Statistics, there were 805 work-related fatalities due to falls and slips in 2021. This tragic number of workplace fatalities shows the importance of fall protection in your manufacturing facility.

As the owner and manager of a manufacturing facility, there is a huge financial risk alongside the tragedy of human injury or death.

A 2022 Fall Report from the CDC shows that Fall injuries cause a considerable financial burden on employers. Workers’ Compensation and Medical Claim costs from occupational falls have been estimated to cost over $70 billion annually in the United States. This leads to rising insurance costs, reduced productivity, and risks of financial loss from litigation.

With the right protocols and policies in place, this number could have been dramatically reduced.

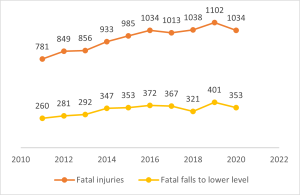

(Fatal injuries and falls in the U.S. construction industry, 2011–2021 Source: CDC)

What Causes Falls in The Workplace?

While every manufacturing facility is unique, there are a number of common factors that can contribute to falls in the workplace.

These fall risks can include:

● Uneven or slippery surfaces on the factory floor

● Open-sided manufacturing equipment

● Insufficient lighting in the working areas

● Improper use of ladders, steps, and scaffolding

● Fatigue of workers due to deadlines or overtime

● Distractions such as other people, smartphones, and multi-tasking

As you can see from the list, many of these causes of falls can be avoided and reduced significantly with the correct fall protection training.

Reducing Fall Injuries In Your Facility

As a starting point, here are some useful tips that can help to prevent falls in a factory:

● Keep walkways clear of debris and obstacles.

● Use proper lighting to illuminate walkways and work areas.

● Make sure floors are in good repair and free of cracks, holes, or other hazards.

● Provide employees with non-slip footwear.

● Encourage employees to take their time and be aware of their surroundings when working in areas where there is a risk of falling.

● Provide employees with fall protection training and make sure they understand the importance of using fall protection equipment.

● Conduct regular safety inspections to identify and correct any potential fall hazards.

How To Implement Manufacturing Facility Fall Training

Fall protection training is a critical part of any safety program. Whether your company offers mechanical construction services or you run a manufacturing facility, fall training is essential.

Fall protection training can be provided in a variety of ways, including:

● In-person classroom training for the team

● Online training provided by a registered training organization

● On-the-job training from managers or peers

The best way to provide fall protection training will depend on the specific needs of the organization. However, it is important that all team members receive the same fall protection training.

Help Your Team Understand Fall Injury Risks

Because falls are one of the leading causes of workplace injuries and fatalities, providing employees with the knowledge and skills they need to prevent falls can help to keep your workers safe.

Fall protection training should cover a variety of topics, including:

● Identifying fall hazards

● Assessing the risk of falls

● Selecting and using the appropriate fall protection equipment

● Using fall protection equipment properly

● Responding to falls

Providing your employees with the knowledge and skills they need to prevent workplace falls will help them to better understand the importance of following safety procedures.

All Employees Must Follow Fall Protection Guidelines

All employees should be aware of the consequences of not using fall protection equipment.

Each team member should know about the risks of falls, even from a height of as low as four feet. The more awareness there is around the risks, the more likelihood of following procedures.

All team members should be encouraged to report if they see someone working without the proper protection or not abiding by fall protection guidelines.

To keep your fall training engaging for your team, it is important to:

● Make sure the training is relevant to the employees’ job duties

● Provide opportunities for employees to practice using fall protection equipment

● Reinforce the importance of safety procedures throughout the training

● Follow up to ensure they are using fall protection equipment properly

By providing employees with the knowledge and skills they need to prevent falls, employers can help to keep their workers safe and reduce the risk of workplace injuries and fatalities.

6 Steps To Reduce Fall Risks In Your Facility

As a final point, here are six steps to reduce falls injuries in your manufacturing facility:

● Identify all fall hazards. The first step to preventing workplace falls is to identify potential hazards. This includes things like uneven floors, slippery surfaces, and open-sided equipment.

● Eliminate or control hazards. Once you have identified fall hazards, you need to take steps to eliminate or control them. This may involve things like installing guardrails, providing non-slip flooring, and using safety nets.

● Provide fall prevention training. Employees need to be trained on how to identify and avoid fall hazards. This training should be ongoing and should be tailored to the specific hazards in your factory.

● Enforce safety rules. It is important to enforce safety rules to ensure that employees are following proper procedures. This may involve things like conducting safety inspections and issuing corrective action for violations.

● Use the right equipment. Employees should be provided with the proper fall protection equipment, such as harnesses, lifelines, and anchors. This equipment should be inspected regularly to ensure that it is in good condition.

● Create a culture of safety. A culture of safety is one where employees feel comfortable speaking up about safety concerns. Employers can create a culture of safety by providing training, enforcing safety rules, reporting issues, and setting a good example.

By following these fall protection tips and encouraging your team to take fall risks seriously, you can help to prevent falls in your facility and keep your employees safe.

Gottstein Corporation is an industry leader in industrial and commercial contracting. Our team of highly motivated project managers is dedicated to your satisfaction, from start to finish. For a full list of tools and services, visit our services page.

https://www.gottsteincorporation.com/services/