In the food and beverage industry, upholding rigorous standards of cleanliness and hygiene is fundamental—not only for regulatory compliance but for the safety and quality of every product that leaves the facility. Sanitary design is integral to this, as it directly impacts operational efficiency, adaptability, and, most importantly, consumer safety. Here, we explore why sanitary design is essential and how experienced industrial contractors, like Gottstein Corporation, help food and beverage companies achieve it.

1. Minimizing Contamination Risks

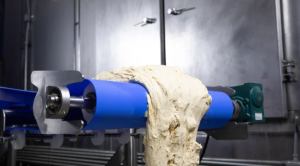

Sanitary design plays a critical role in reducing contamination risks by shaping every aspect of a facility’s layout, from equipment to flooring and ventilation. Contractors employ smooth, easy-to-clean surfaces that prevent the buildup of contaminants and bacteria, while also eliminating tight corners and hidden spaces where residue and moisture could accumulate and promote microbial growth.

2. Meeting Regulatory Standards

Food and beverage manufacturers must comply with stringent regulations from authorities like the FDA, USDA, and various global standards organizations. Sanitary design is a cornerstone for compliance. Contractors ensure that each part of the design adheres to food safety protocols, such as the Hazard Analysis Critical Control Point (HACCP) system, which identifies and controls potential hazards in the manufacturing process.

3. Boosting Operational Efficiency

A sanitary, well-organized facility not only safeguards product quality but also enhances cleaning and maintenance efficiency. Contractors can implement quick-disassembly systems or clean-in-place (CIP) systems that streamline cleaning and reduce downtime. This efficiency is vital for manufacturers dealing with perishable products, leading to faster changeovers and increased productivity.

4. Supporting Sustainability and Reducing Waste

Sanitary design also aligns with sustainability goals. By using easy-to-clean surfaces and efficient waste control systems, facilities minimize the need for harsh chemicals and excessive water. Thoughtful design supports waste reduction, helping facilities operate more sustainably while maintaining high cleanliness standards.

5. Flexible Facility Layouts for Future Adaptability

The food and beverage industry continuously evolves to meet consumer demands for new flavors, formats, and health-conscious options. Facilities designed with flexibility in mind can quickly adjust to these changes. Contractors can create modular spaces that easily accommodate new processes, products, or packaging lines without compromising on sanitary requirements.

Choosing an Experienced Industrial Contractor for Sanitary Design

Not all contractors are experienced in the unique demands of food and beverage production environments. Selecting a contractor with expertise in sanitary facility design is essential. Skilled contractors understand specific requirements—from material selection to air handling and waste management—ensuring that facilities are built to the highest standards of safety and efficiency.

In a landscape where food safety and consumer trust are paramount, investing in sanitary facility design is not just about regulatory compliance; it’s a strategic advantage. By partnering with knowledgeable industrial contractors like Gottstein Corporation, food and beverage manufacturers can ensure their facilities are optimized for safety, productivity, and adaptability. Explore our services to learn more about how we support the food and beverage industry’s unique needs.